| Availability: | |

|---|---|

| Quantity: | |

| Drive Mode | 6x4 |

| Brand | CAMC |

| Fuel Type | Electric |

| Emission Standard | Zero |

| Max. Speed (km/h) | 85 |

| Condition | New |

| Battery type | Lithium iron phosphate |

| Rated power/horsepower(kw/hp) | 245/345 |

| Video outgoing-inspection | Provided |

| Charging time | 1h |

| Dimension(L*W*H) | 9000*2500*3920mm |

| Place of Origin | China |

Mixing System Configuration

The mixing drum is welded from wear-resistant alloy steel, with spiral blade structure inside. Equipped with an independent hydraulic drive system (adjustable speed 5-14r/min), it effectively prevents concrete segregation. A discharge chute and 溜槽 are set at the tail of the drum, supporting multi-angle adjustment to fit the material receiving needs of different construction equipment.

Chassis & Power Design

It adopts a heavy-duty dedicated chassis with a multi-leaf spring suspension system, bearing capacity over 25 tons. The power system is matched with a high-torque engine and 6-speed gearbox, balancing heavy-load starting performance and road driving efficiency, with a maximum speed of up to 80km/h.

Safety & Compliance Configuration

The vehicle is equipped with an anti-roll warning system and drum status monitoring device, complying with road transport safety standards. The cab integrates reverse camera, tire pressure monitoring and other functions to enhance operational safety.

High Transport Efficiency

The mixing drum can operate continuously for 10 hours, adapting to high-frequency transfer needs in a single day; the drum discharge speed is controlled at 1.5-2 minutes per cubic meter, enabling quick material delivery and reducing construction waiting time.

Wide Adaptability

It is suitable for short-distance high-frequency transport in urban housing projects, as well as long-distance distribution in suburban infrastructure projects; the anti-corrosion coating of the drum allows long-term operation in complex environments such as rainy and high-humidity areas.

Controllable Operation & Maintenance Costs

Key components adopt modular design, making replacement of vulnerable parts (such as blades and seals) convenient; the chassis and power system have strong universality, with wide after-sales maintenance network coverage, reducing long-term operation and maintenance difficulties.

Civil construction projects: Point-to-point transport of ready-mixed concrete from batching plants to building construction sites;

Municipal infrastructure projects: Large-batch concrete distribution for roads, bridges, subways and other projects;

Rural infrastructure projects: Material transfer needs for small-scale projects such as village roads and water conservancy facilities.

| Drive Mode | 6x4 |

| Brand | CAMC |

| Fuel Type | Electric |

| Emission Standard | Zero |

| Max. Speed (km/h) | 85 |

| Condition | New |

| Battery type | Lithium iron phosphate |

| Rated power/horsepower(kw/hp) | 245/345 |

| Video outgoing-inspection | Provided |

| Charging time | 1h |

| Dimension(L*W*H) | 9000*2500*3920mm |

| Place of Origin | China |

Mixing System Configuration

The mixing drum is welded from wear-resistant alloy steel, with spiral blade structure inside. Equipped with an independent hydraulic drive system (adjustable speed 5-14r/min), it effectively prevents concrete segregation. A discharge chute and 溜槽 are set at the tail of the drum, supporting multi-angle adjustment to fit the material receiving needs of different construction equipment.

Chassis & Power Design

It adopts a heavy-duty dedicated chassis with a multi-leaf spring suspension system, bearing capacity over 25 tons. The power system is matched with a high-torque engine and 6-speed gearbox, balancing heavy-load starting performance and road driving efficiency, with a maximum speed of up to 80km/h.

Safety & Compliance Configuration

The vehicle is equipped with an anti-roll warning system and drum status monitoring device, complying with road transport safety standards. The cab integrates reverse camera, tire pressure monitoring and other functions to enhance operational safety.

High Transport Efficiency

The mixing drum can operate continuously for 10 hours, adapting to high-frequency transfer needs in a single day; the drum discharge speed is controlled at 1.5-2 minutes per cubic meter, enabling quick material delivery and reducing construction waiting time.

Wide Adaptability

It is suitable for short-distance high-frequency transport in urban housing projects, as well as long-distance distribution in suburban infrastructure projects; the anti-corrosion coating of the drum allows long-term operation in complex environments such as rainy and high-humidity areas.

Controllable Operation & Maintenance Costs

Key components adopt modular design, making replacement of vulnerable parts (such as blades and seals) convenient; the chassis and power system have strong universality, with wide after-sales maintenance network coverage, reducing long-term operation and maintenance difficulties.

Civil construction projects: Point-to-point transport of ready-mixed concrete from batching plants to building construction sites;

Municipal infrastructure projects: Large-batch concrete distribution for roads, bridges, subways and other projects;

Rural infrastructure projects: Material transfer needs for small-scale projects such as village roads and water conservancy facilities.

We are a company specializing in foreign trade,and have very rich experience in sea transportation.We have exported to More than 60 countries and regions in Eastern Europe, North Africa, Southeast Asia and South America.According to past cases, each of our goods is intact and delivered to customers on schedule.

We are a company specializing in foreign trade,and have very rich experience in sea transportation.We have exported to More than 60 countries and regions in Eastern Europe, North Africa, Southeast Asia and South America.According to past cases, each of our goods is intact and delivered to customers on schedule.

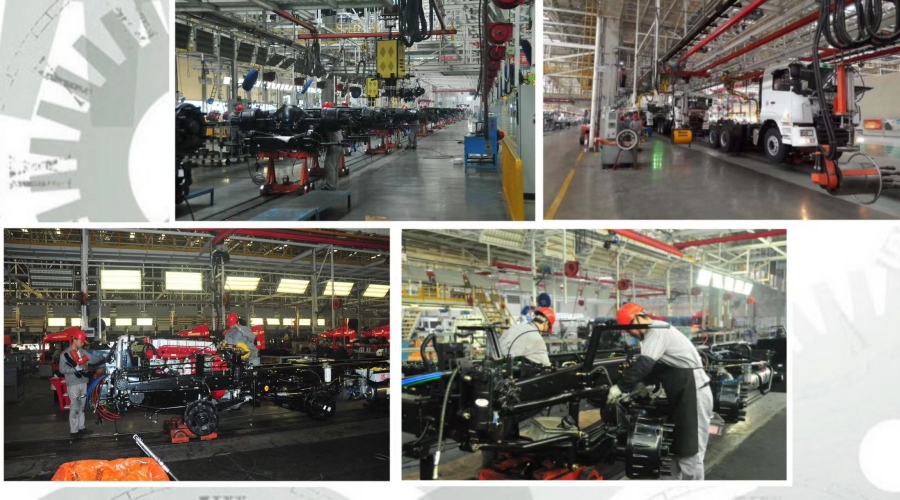

CAMC is the national priority production and research development base of heavy truck, special purpose heavy vehicle and spare parts, which is also the state mainly supports enterprise.

CAMC was found in 1970s and we are the only one truck enterprise in China which is capable of produing everything by our own including engine, gearbox, axles, chassis, cabin and so on.

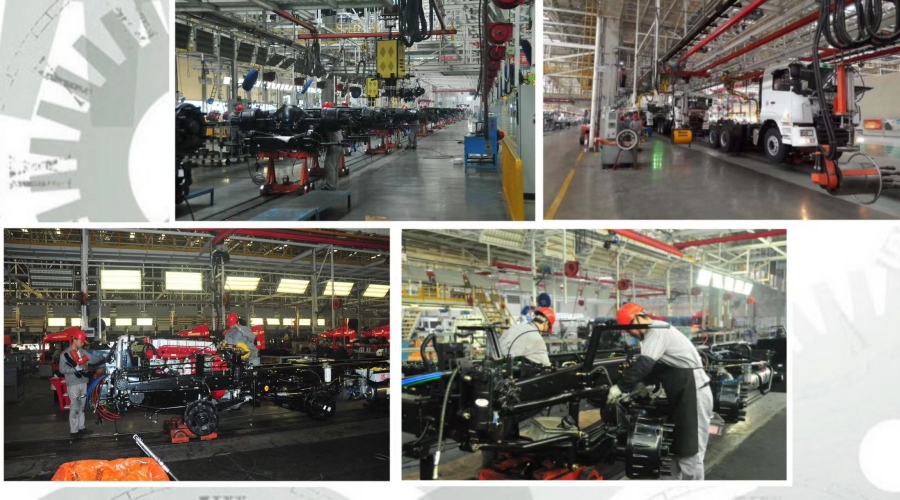

CAMC is the national priority production and research development base of heavy truck, special purpose heavy vehicle and spare parts, which is also the state mainly supports enterprise.

CAMC was found in 1970s and we are the only one truck enterprise in China which is capable of produing everything by our own including engine, gearbox, axles, chassis, cabin and so on.