| Availability: | |

|---|---|

| Quantity: | |

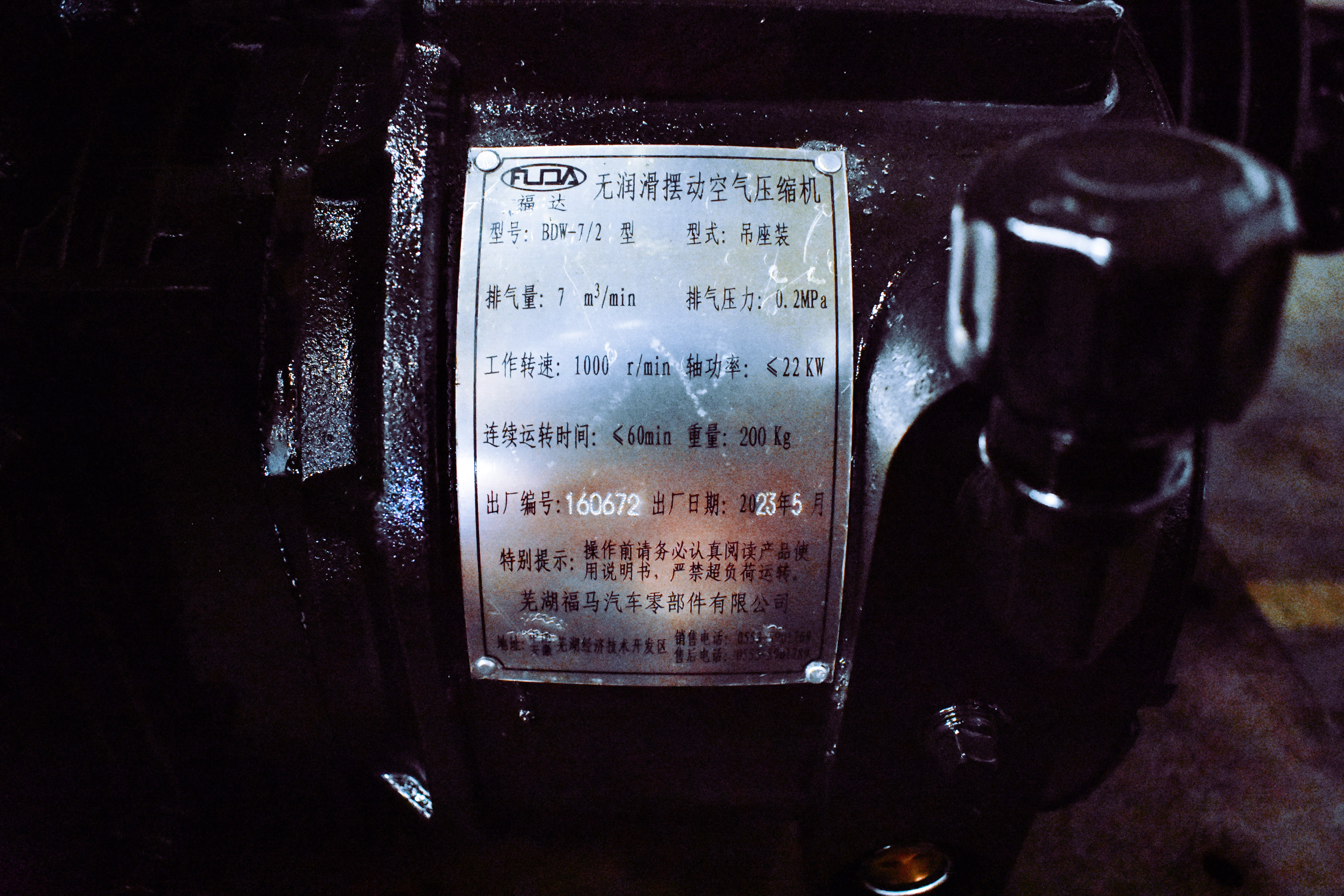

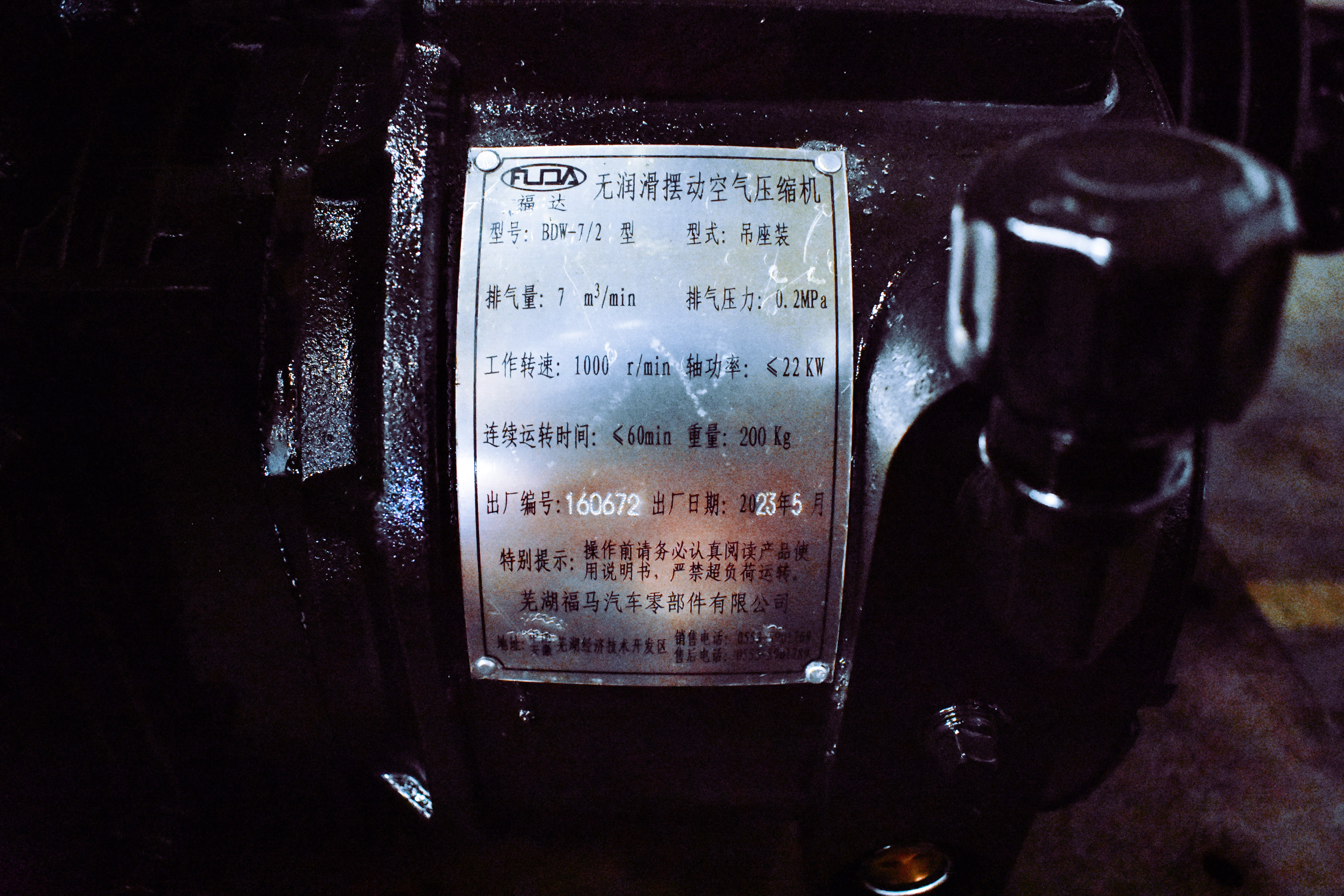

| Item | Unit/Model | BDW -6/2 | BDW -7/2 | BDW -8/2 | BDW -9/2 | BDW -10/2 | BDW -10/2-S | BDW -12/2-S | BDW -16/2-S |

| Displacement | m³/min | 6 | 7 | 8 | 9 | 10 | 10 | 12 | 16 |

| Discharge pressure | MPa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Axial power | Kw | ≤25.5 | ≤29 | ≤33 | ≤35 | ≤40 | ≤40 | ≤44 | ≤56 |

| Max rotate speed | R/min | 1250 | 1200 | 1150 | 1100 | 1100 | 1000 | 1000 | 950 |

| Durative working time | Min | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

| Protective moment | N·m | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 400 |

| Inspiration temperature | ℃ | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Exhaust temperature | ℃ | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 |

| Weight | Kg | 190 | 195 | 209 | 216 | 230 | 366 | 376 | 430 |

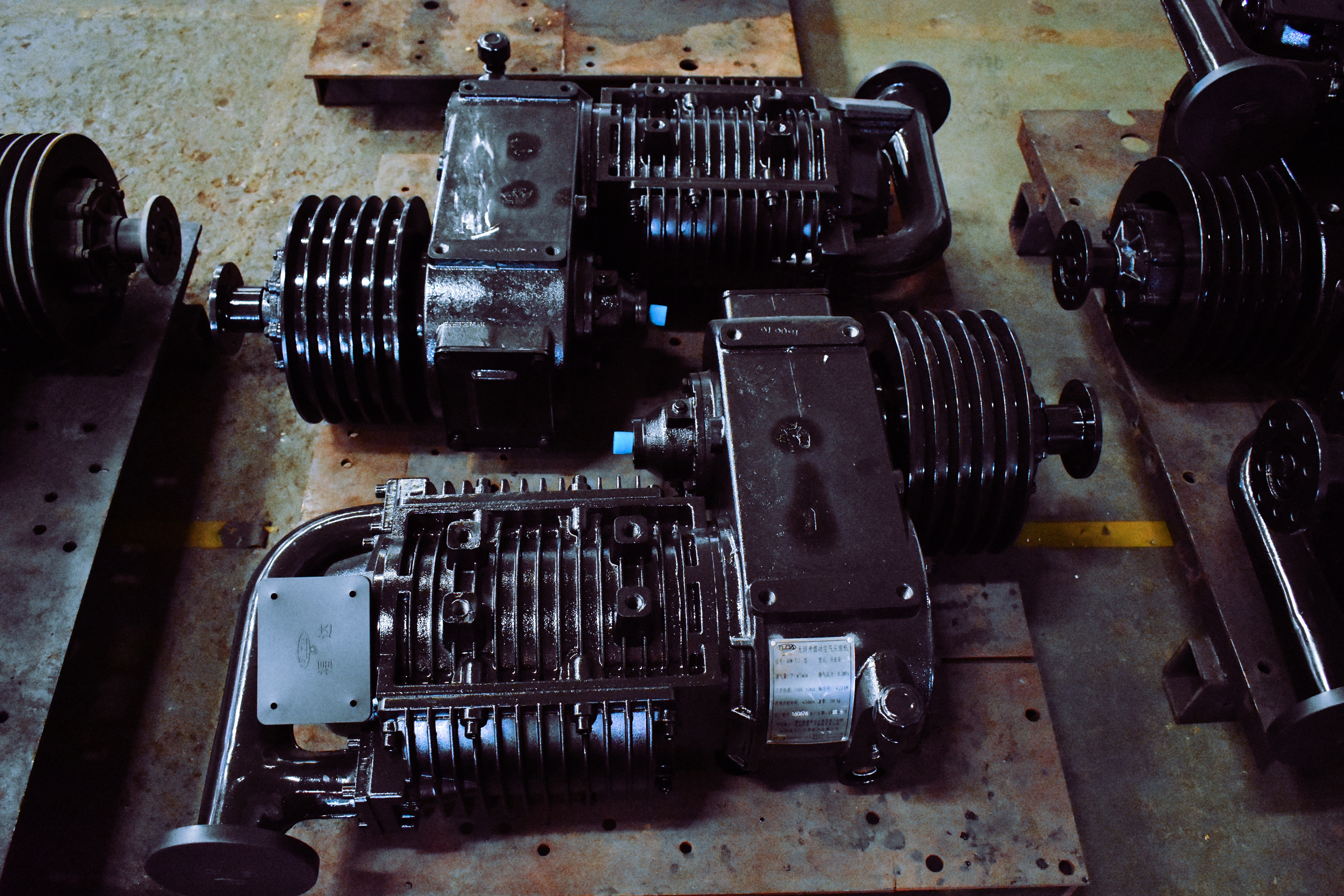

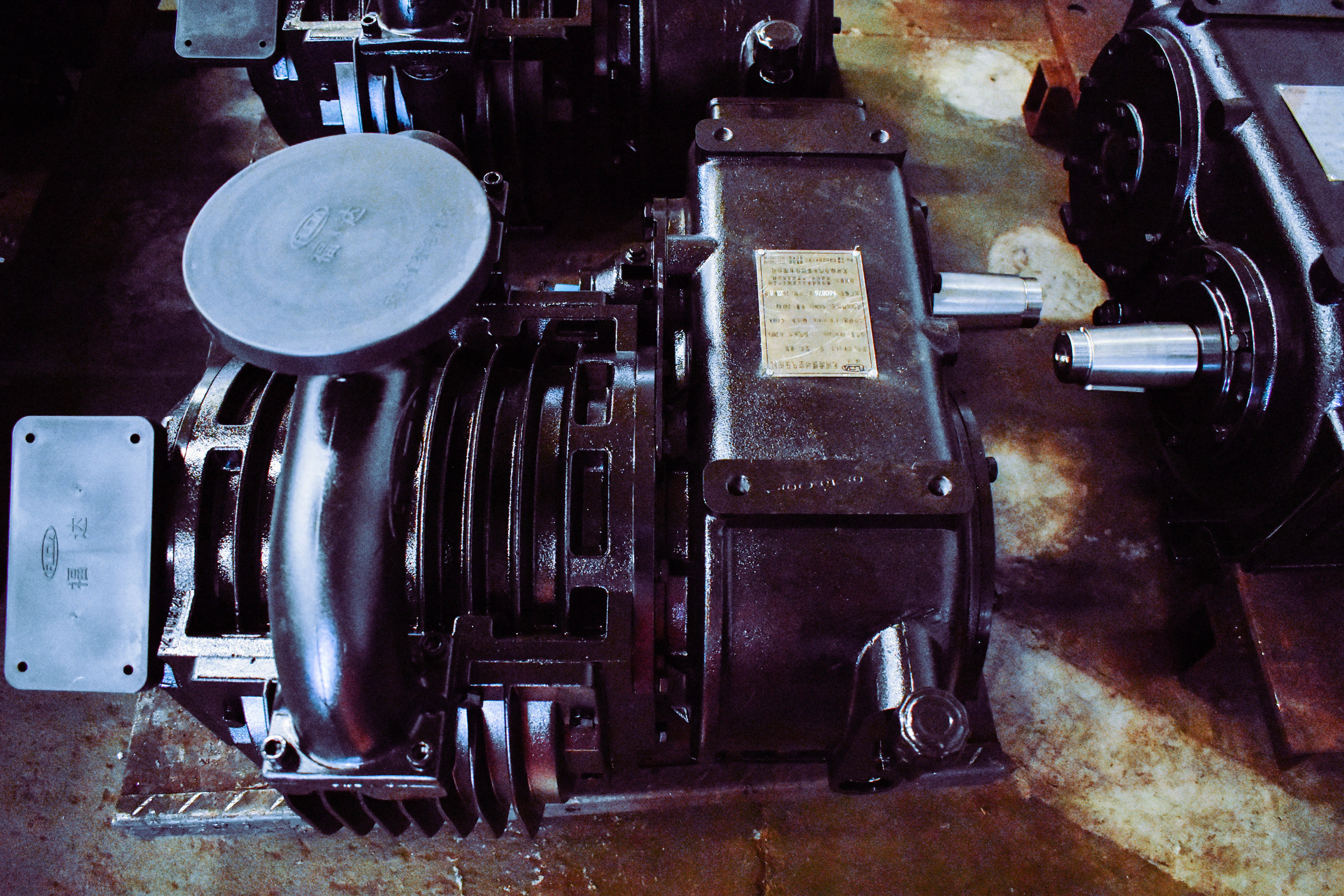

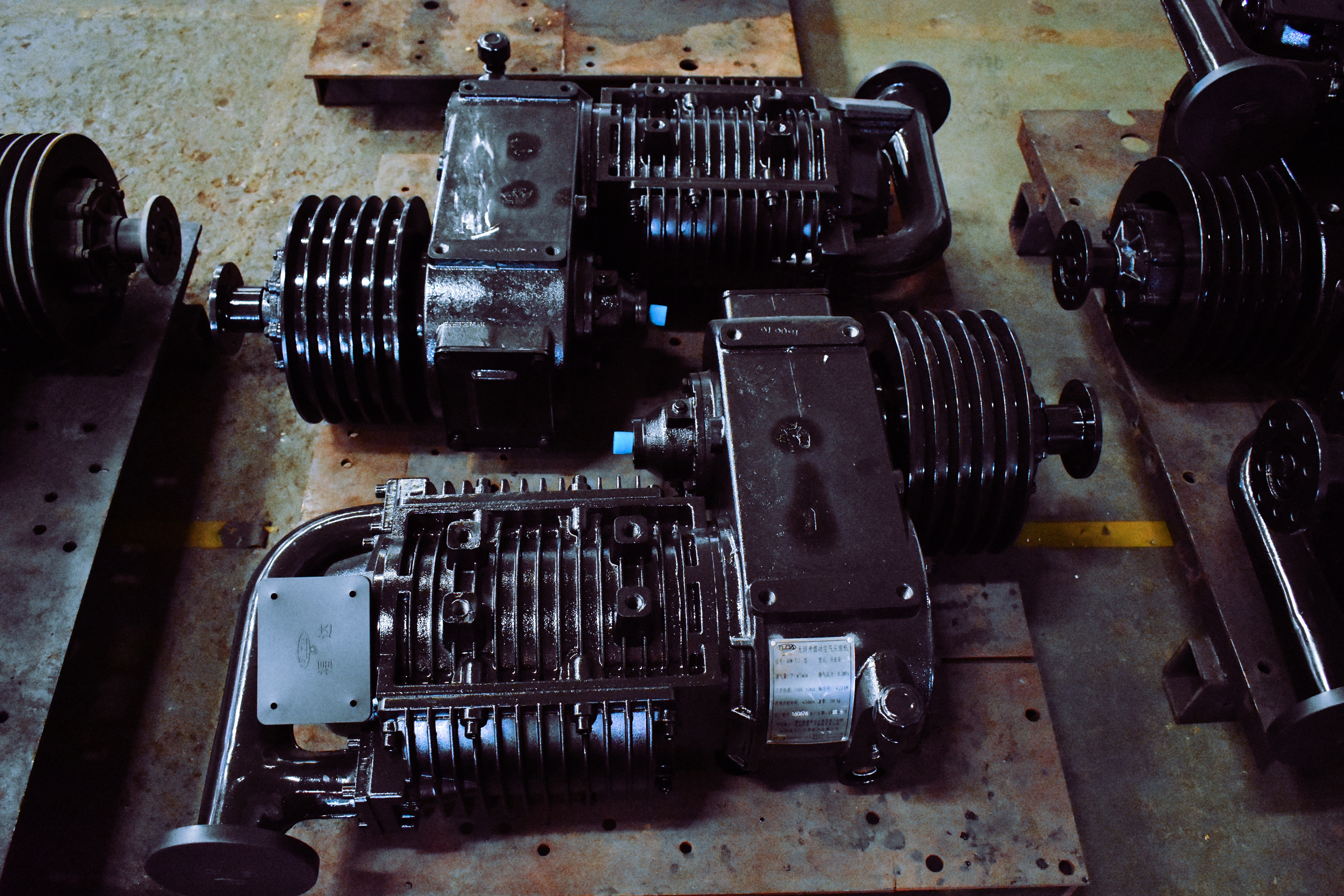

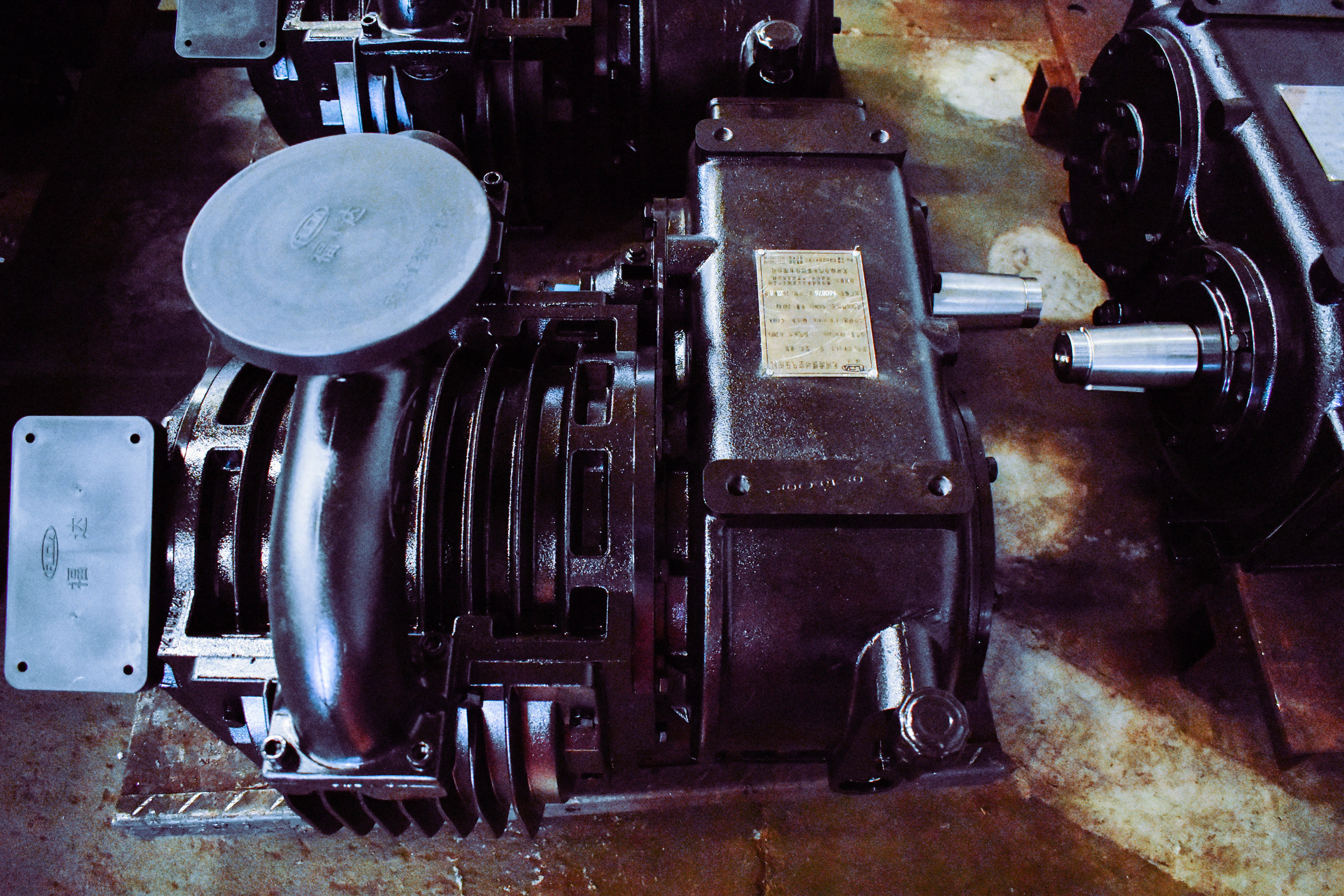

The CAMC BDW-FUDA oil-free rotary air compressor is a brand-new fixed screw device powered by diesel, suitable for various scenarios such as driving industrial pneumatic tools, inflating small-scale engineering projects, and providing auxiliary air supply for equipment. The machine dimensions are 122×75×55 cm, with a net weight of 235 KG. It maintains a stable working pressure of 2 bar and can deliver clean, oil-free compressed air, meeting the basic air quality requirements of most operational environments.

1.Oil-Free & Clean for Precision Scenarios

Featuring an oil-free lubrication structure, the compressed air contains zero oil content—effectively preventing air-source contamination of equipment, workpieces, or production materials. It is especially suitable for applications requiring air purity, such as spraying and precision instrument supporting.

2.Screw Structure for Stable Operation

Screw compression technology significantly reduces vibration and noise during operation, while extending continuous working hours. This minimizes work interruptions and ensures consistent productivity.

3.Diesel-Powered for Grid Independence

Powered by diesel, it does not rely on external power grids—enabling independent, stable operation in off-grid environments like outdoor construction sites or remote work locations, making it perfect for mobile or non-electrified tasks.

4.Stationary Configuration for Easy Installation

The stationary design allows for quick deployment once positioned, with no need for frequent layout adjustments. It is ideal for long-term fixed-workstation operations.

1.Preparation Phase

Place the device on a flat, well-ventilated site. Check that the diesel tank has sufficient fuel, and verify that all connections are tight and seals are leak-free.

2.Startup Procedure

Open the diesel valve, then pull the starter (or press the electric start button if equipped). Allow the device to idle for 1-2 minutes until stable, then adjust to the working speed.

3.Operation Monitoring

Monitor the pressure gauge in real time during operation to ensure the working pressure remains within 2 bar. If abnormal pressure fluctuations or unusual noises occur, stop the machine immediately for inspection.

4.Shutdown Steps

Reduce the speed to idle, run for 30 seconds, then close the diesel valve. Once the device has completely stopped, clean dust and debris from the surface to maintain daily upkeep.

1.Q: What is the recommended continuous working time for the device?

A: We recommend no more than 4 hours of continuous operation at a time. After that, shut down the machine to cool for 15-20 minutes to avoid overheating and extend the device’s lifespan.

2.Q: Does the oil-free device require regular maintenance?

A: Yes. We advise checking and cleaning the air intake filter monthly (replace if heavily clogged), and inspecting the body seals quarterly to prevent air leaks that reduce efficiency.

3.Q: Can the working pressure be adjusted manually?

A: The working pressure of this model is preset to 2 bar and cannot be adjusted independently. For higher pressure requirements, please select a model with the corresponding pressure rating.

| Item | Unit/Model | BDW -6/2 | BDW -7/2 | BDW -8/2 | BDW -9/2 | BDW -10/2 | BDW -10/2-S | BDW -12/2-S | BDW -16/2-S |

| Displacement | m³/min | 6 | 7 | 8 | 9 | 10 | 10 | 12 | 16 |

| Discharge pressure | MPa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Axial power | Kw | ≤25.5 | ≤29 | ≤33 | ≤35 | ≤40 | ≤40 | ≤44 | ≤56 |

| Max rotate speed | R/min | 1250 | 1200 | 1150 | 1100 | 1100 | 1000 | 1000 | 950 |

| Durative working time | Min | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

| Protective moment | N·m | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 400 |

| Inspiration temperature | ℃ | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Exhaust temperature | ℃ | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 |

| Weight | Kg | 190 | 195 | 209 | 216 | 230 | 366 | 376 | 430 |

The CAMC BDW-FUDA oil-free rotary air compressor is a brand-new fixed screw device powered by diesel, suitable for various scenarios such as driving industrial pneumatic tools, inflating small-scale engineering projects, and providing auxiliary air supply for equipment. The machine dimensions are 122×75×55 cm, with a net weight of 235 KG. It maintains a stable working pressure of 2 bar and can deliver clean, oil-free compressed air, meeting the basic air quality requirements of most operational environments.

1.Oil-Free & Clean for Precision Scenarios

Featuring an oil-free lubrication structure, the compressed air contains zero oil content—effectively preventing air-source contamination of equipment, workpieces, or production materials. It is especially suitable for applications requiring air purity, such as spraying and precision instrument supporting.

2.Screw Structure for Stable Operation

Screw compression technology significantly reduces vibration and noise during operation, while extending continuous working hours. This minimizes work interruptions and ensures consistent productivity.

3.Diesel-Powered for Grid Independence

Powered by diesel, it does not rely on external power grids—enabling independent, stable operation in off-grid environments like outdoor construction sites or remote work locations, making it perfect for mobile or non-electrified tasks.

4.Stationary Configuration for Easy Installation

The stationary design allows for quick deployment once positioned, with no need for frequent layout adjustments. It is ideal for long-term fixed-workstation operations.

1.Preparation Phase

Place the device on a flat, well-ventilated site. Check that the diesel tank has sufficient fuel, and verify that all connections are tight and seals are leak-free.

2.Startup Procedure

Open the diesel valve, then pull the starter (or press the electric start button if equipped). Allow the device to idle for 1-2 minutes until stable, then adjust to the working speed.

3.Operation Monitoring

Monitor the pressure gauge in real time during operation to ensure the working pressure remains within 2 bar. If abnormal pressure fluctuations or unusual noises occur, stop the machine immediately for inspection.

4.Shutdown Steps

Reduce the speed to idle, run for 30 seconds, then close the diesel valve. Once the device has completely stopped, clean dust and debris from the surface to maintain daily upkeep.

1.Q: What is the recommended continuous working time for the device?

A: We recommend no more than 4 hours of continuous operation at a time. After that, shut down the machine to cool for 15-20 minutes to avoid overheating and extend the device’s lifespan.

2.Q: Does the oil-free device require regular maintenance?

A: Yes. We advise checking and cleaning the air intake filter monthly (replace if heavily clogged), and inspecting the body seals quarterly to prevent air leaks that reduce efficiency.

3.Q: Can the working pressure be adjusted manually?

A: The working pressure of this model is preset to 2 bar and cannot be adjusted independently. For higher pressure requirements, please select a model with the corresponding pressure rating.

content is empty!