| Availability: | |

|---|---|

| Quantity: | |

| Item | Unit/Model | BDW -10/2-S | BDW -12/2-S | BDW -16/2 |

| Displacement | m³/min | 10 | 12 | 16 |

| Discharge pressure | MPa | 0.2 | 0.2 | 0.2 |

| Axial power | Kw | ≤40 | ≤44 | ≤56 |

| Max rotate speed | R/min | 1000 | 1000 | 950 |

| Durative working time | Min | ≤60 | ≤60 | ≤60 |

| Protective moment | N·m | 400 | 400 | 400 |

| Inspiration temperature | ℃ | ≤40 | ≤40 | ≤40 |

| Exhaust temperature | ℃ | ≤200 | ≤200 | ≤200 |

| Weight | Kg | 366 | 376 | 430 |

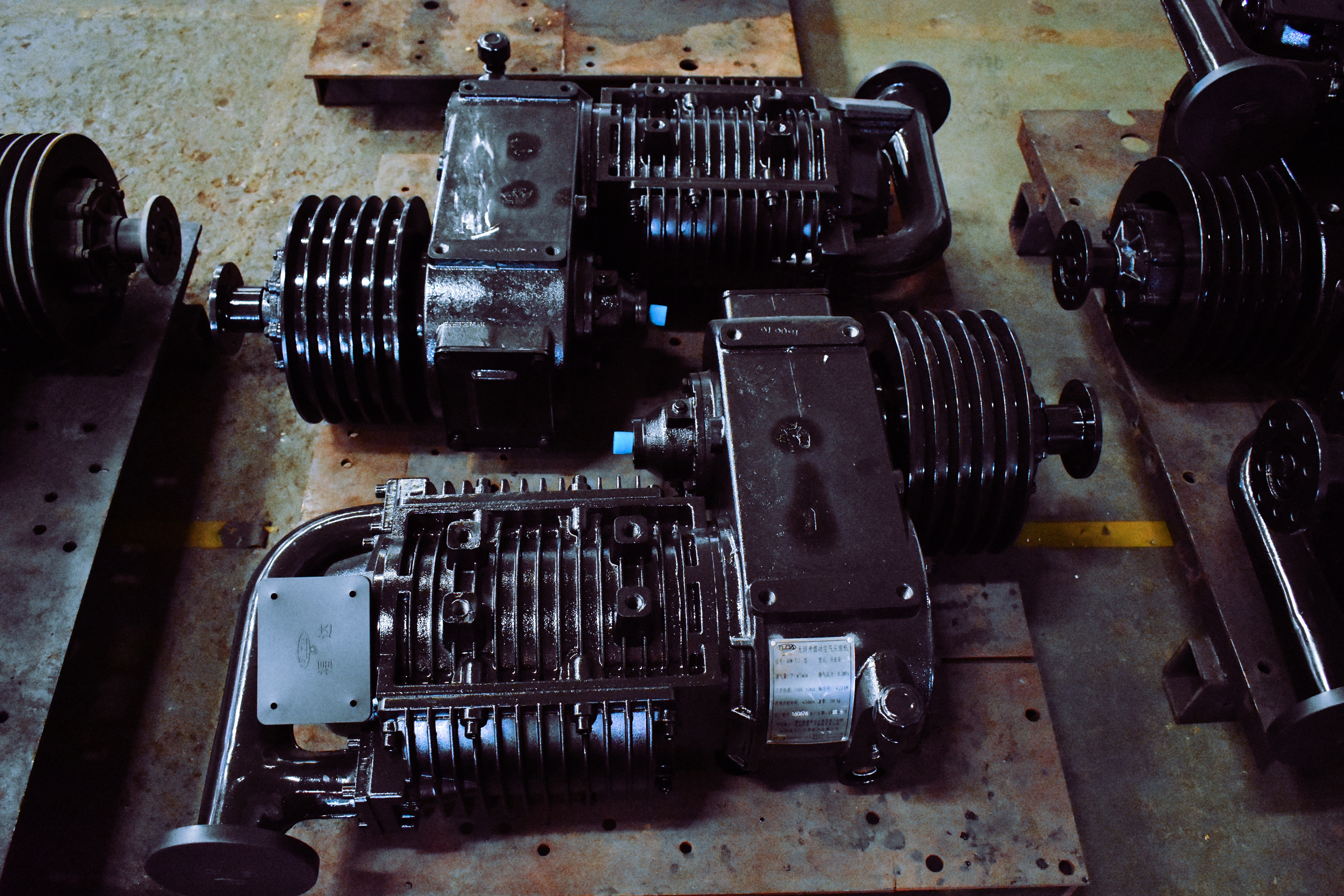

No lubrication swings in air compressors volume and typegenus of the connecting rod. under the four of the crank rockersorganization,through the drive shaftis ( round ) the crank therotor to 90 degrees reciprocating. periodic change in thecylinder capacity for work, inhale, compressed, the four work. ina cylinder of a seal is closed with each other, in exercise ofsurfaces seal is lubricated by the lubricated oil itself, therefore,the compressed air is pure oil.

Oil-Free, Purity Guaranteed: Compressed air output is 100% oil-free—no contamination risk for sensitive applications (critical for industries where clean air matters).

Patent-Backed Performance: The BDW series holds 9 national patents, so you’re getting a design refined for efficiency and reliability (no flimsy, untested hardware here).

Rock-Solid Stability: Engineered to run consistently, even under heavy, prolonged use—minimizes downtime for your operations.

Industry-Leading Design: Ranks among the top domestic advanced models, with additional 3 patents for its zero-defect production process (quality you can trust).

Specialized Automobile Manufacturing: Powers pneumatic tools, painting systems, and assembly line equipment (clean air prevents paint/part contamination).

Industrial Workshops: Supplies oil-free compressed air for precision tools, packaging machinery, and material handling systems.

Heavy-Duty Vehicle Maintenance: Runs air-powered lifts, impact wrenches, and tire inflators in commercial truck/vehicle repair shops.

Customer Reviews

"We use this compressor in our commercial truck assembly plant in Texas. The oil-free air is a must for our painting stations—no more specks of oil ruining finishes. It’s run 8-hour shifts 5 days a week for 6 months now, and we haven’t had a single hiccup. Way more reliable than our old lubricated unit."

— Jake, Plant Manager at U.S. Commercial Vehicle Manufacturer

"As a workshop owner in Germany, I need tools that hold up to daily use. This CAMC compressor delivers steady, clean air for our tire changers and impact wrenches. The fact that it’s patent-backed gave me confidence to buy—and it’s lived up to it. No maintenance headaches so far." — Klaus, Owner of German Heavy-Duty Vehicle Repair Shop

FAQ

Q: How durable is this compressor for heavy use?

A: It’s built for industrial-grade workloads—engineered for stability even during prolonged, daily operation (many users run it 8+ hour shifts with consistent performance).Q: What makes the BDW series "advanced" compared to other compressors?

A: It holds 9 national patents for its swing-cylinder design and zero-defect production, plus it’s ranked among domestic top-tier models—translating to better efficiency and reliability.| Item | Unit/Model | BDW -10/2-S | BDW -12/2-S | BDW -16/2 |

| Displacement | m³/min | 10 | 12 | 16 |

| Discharge pressure | MPa | 0.2 | 0.2 | 0.2 |

| Axial power | Kw | ≤40 | ≤44 | ≤56 |

| Max rotate speed | R/min | 1000 | 1000 | 950 |

| Durative working time | Min | ≤60 | ≤60 | ≤60 |

| Protective moment | N·m | 400 | 400 | 400 |

| Inspiration temperature | ℃ | ≤40 | ≤40 | ≤40 |

| Exhaust temperature | ℃ | ≤200 | ≤200 | ≤200 |

| Weight | Kg | 366 | 376 | 430 |

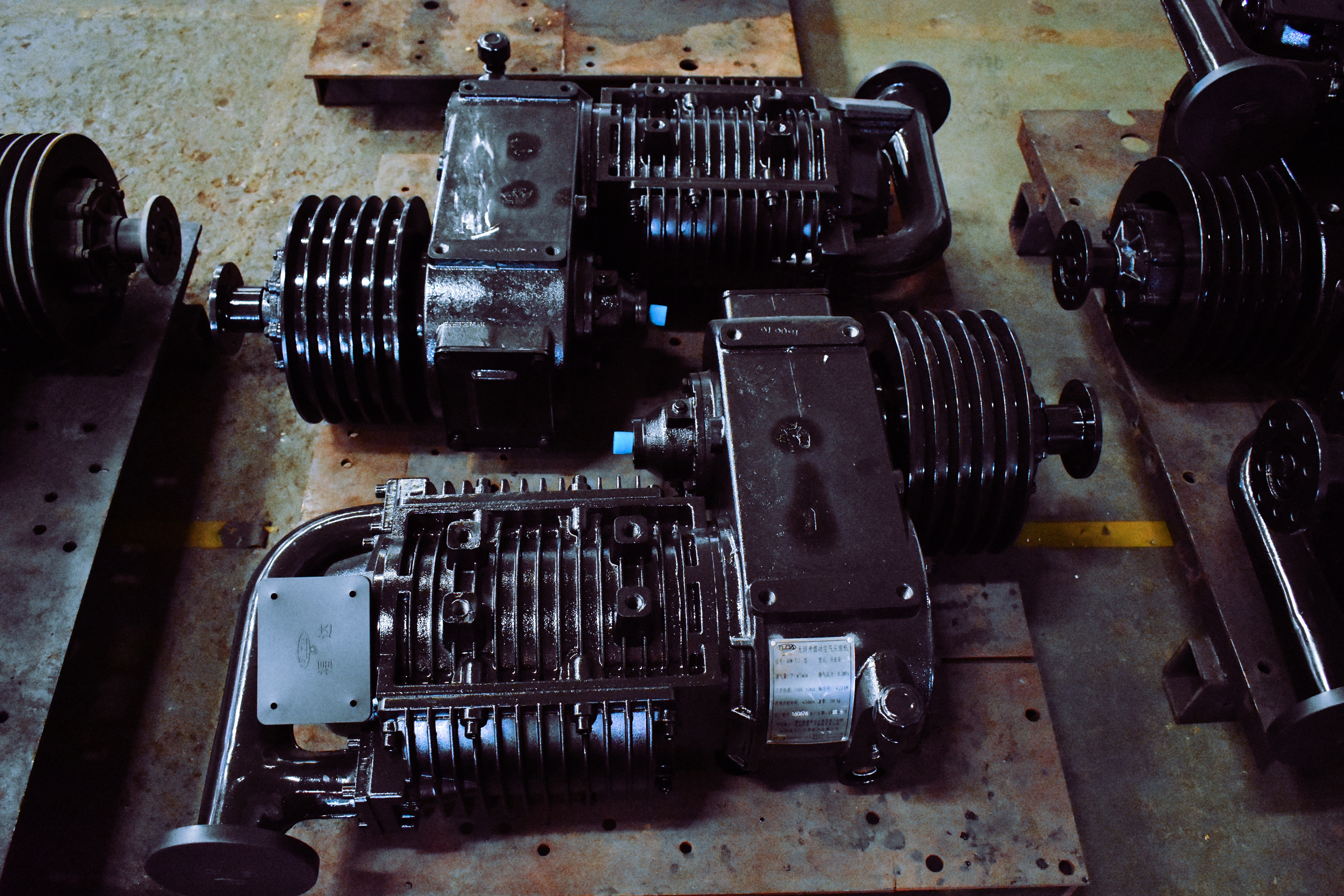

No lubrication swings in air compressors volume and typegenus of the connecting rod. under the four of the crank rockersorganization,through the drive shaftis ( round ) the crank therotor to 90 degrees reciprocating. periodic change in thecylinder capacity for work, inhale, compressed, the four work. ina cylinder of a seal is closed with each other, in exercise ofsurfaces seal is lubricated by the lubricated oil itself, therefore,the compressed air is pure oil.

Oil-Free, Purity Guaranteed: Compressed air output is 100% oil-free—no contamination risk for sensitive applications (critical for industries where clean air matters).

Patent-Backed Performance: The BDW series holds 9 national patents, so you’re getting a design refined for efficiency and reliability (no flimsy, untested hardware here).

Rock-Solid Stability: Engineered to run consistently, even under heavy, prolonged use—minimizes downtime for your operations.

Industry-Leading Design: Ranks among the top domestic advanced models, with additional 3 patents for its zero-defect production process (quality you can trust).

Specialized Automobile Manufacturing: Powers pneumatic tools, painting systems, and assembly line equipment (clean air prevents paint/part contamination).

Industrial Workshops: Supplies oil-free compressed air for precision tools, packaging machinery, and material handling systems.

Heavy-Duty Vehicle Maintenance: Runs air-powered lifts, impact wrenches, and tire inflators in commercial truck/vehicle repair shops.

Customer Reviews

"We use this compressor in our commercial truck assembly plant in Texas. The oil-free air is a must for our painting stations—no more specks of oil ruining finishes. It’s run 8-hour shifts 5 days a week for 6 months now, and we haven’t had a single hiccup. Way more reliable than our old lubricated unit."

— Jake, Plant Manager at U.S. Commercial Vehicle Manufacturer

"As a workshop owner in Germany, I need tools that hold up to daily use. This CAMC compressor delivers steady, clean air for our tire changers and impact wrenches. The fact that it’s patent-backed gave me confidence to buy—and it’s lived up to it. No maintenance headaches so far." — Klaus, Owner of German Heavy-Duty Vehicle Repair Shop

FAQ

Q: How durable is this compressor for heavy use?

A: It’s built for industrial-grade workloads—engineered for stability even during prolonged, daily operation (many users run it 8+ hour shifts with consistent performance).Q: What makes the BDW series "advanced" compared to other compressors?

A: It holds 9 national patents for its swing-cylinder design and zero-defect production, plus it’s ranked among domestic top-tier models—translating to better efficiency and reliability.content is empty!